There are different methods to make drop stitch fabric, but one possible process is as follows:

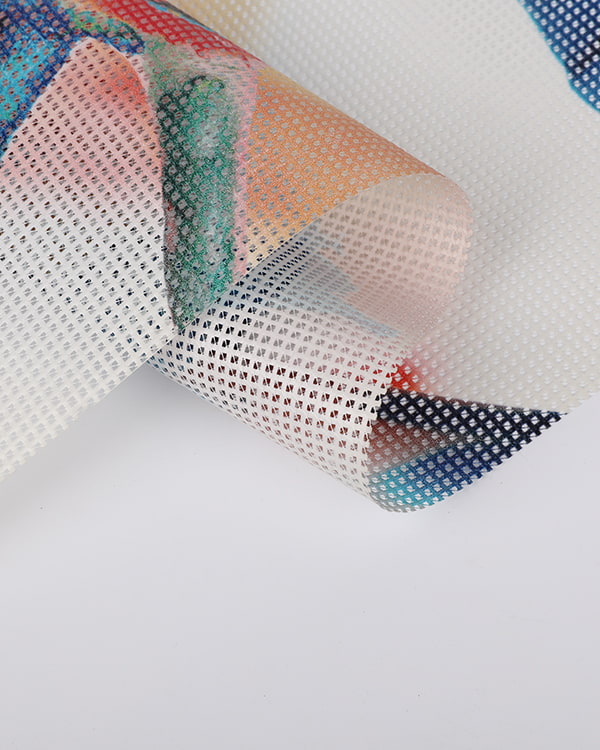

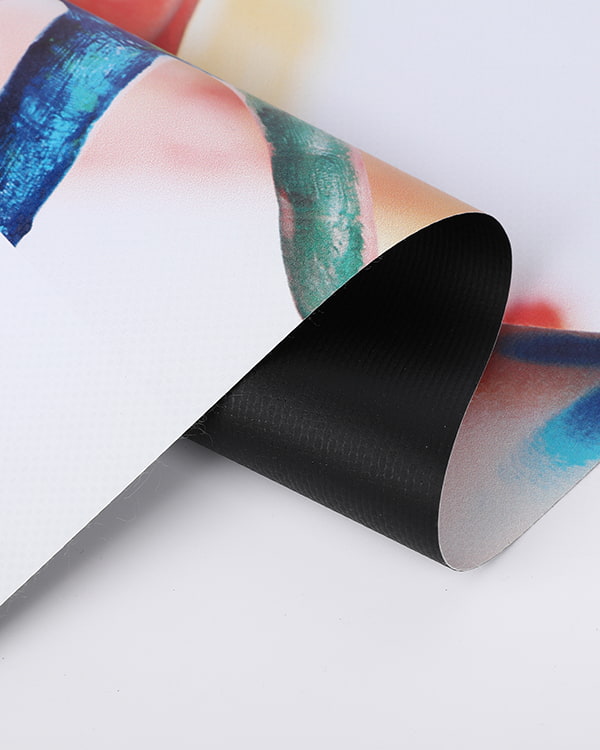

Prepare the base fabric: This can be done by knitting or weaving a fabric using a suitable yarn, such as polyester or nylon. The fabric should be strong and durable, and have a consistent thickness and width.

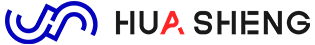

Create the drop stitch pattern: This involves attaching threads at specific intervals to the base fabric, running perpendicular to it. The threads can be sewn, glued, or heat-welded to the fabric, depending on the type of yarn and the desired strength.

dropstitchfabricforinflatablesupandpaddleboard.jpg)

Inflate the fabric: Once the drop stitch pattern is complete, the fabric is inflated with air to create a stable and rigid structure. The level of inflation can be controlled to achieve the desired level of firmness and flexibility.

Finish the fabric: Once the fabric is inflated, it can be trimmed and sealed to create a smooth and clean edge. Additional steps such as coating, laminating, or printing can also be applied to enhance the properties or appearance of the fabric.

Quality check and packing

Keep in mind that this process can be quite complex and requires specialized machinery and skilled personnel to produce high-quality drop stitch fabric.

English

English 中文简体

中文简体 русский

русский

浙公网安备33048102240301

浙公网安备33048102240301