What is the principle behind the UV stability of the PVC resin used in PVC Membrane Structure Fabric?

The UV stability of PVC (Polyvinyl Chloride) resin used in PVC membrane structure fabric is achieved through a combination of factors, prima...

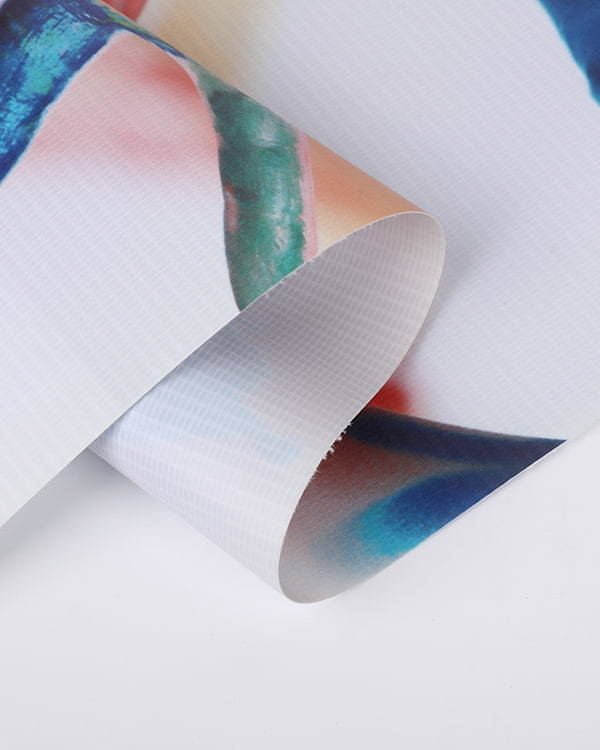

PVC Flex Banner are suitable for indoor and outdoor short period or long term advertisings such as b...

More details

PVC Flex Banner are suitable for indoor and outdoor short period or long term advertisings such as b...

More details

PVC Flex Banner are suitable for indoor and outdoor short period or long term advertisings such as b...

More details

PVC Flex Banner are suitable for indoor and outdoor short period or long term advertisings such as b...

More details

PVC Flex Banner are suitable for indoor and outdoor short period or long term advertisings such as b...

More details

PVC Flex Banner are suitable for indoor and outdoor short period or long term advertisings such as b...

More details

PVC Flex Banner are suitable for indoor and outdoor short period or long term advertisings such as b...

More details

PVC Flex Banner are suitable for indoor and outdoor short period or long term advertisings such as b...

More details

PVC Flex Banner are suitable for indoor and outdoor short period or long term advertisings such as b...

More detailsThe UV stability of PVC (Polyvinyl Chloride) resin used in PVC membrane structure fabric is achieved through a combination of factors, prima...

To ensure that PVC banner hemming tape sticks smoothly and wrinkle-free on a PVC flex banner, it's important to follow a careful and precise...

Distributing grommets or attachment points on PVC flex banners in a strategic manner is crucial for ensuring optimal display and preventing ...

Variable air pressure systems used in inflatable fabric structures typically employ pressure sensors to sense and regulate air pressure with...

The production steps of PVC Flex Banner

Here are the general production steps involved in the manufacture of PVC flex banners:

Mixing the PVC paste: The first step in the production of PVC flex banners is to mix the PVC paste. PVC paste is made by blending PVC resin with plasticizers, stabilizers, pigments, and other additives.

Coating the PVC paste: The mixed PVC paste is then coated onto a polyester fabric using a specialized coating machine. The fabric is passed through the machine, and the PVC paste is spread evenly onto it.

Heating and drying the coated fabric: The coated fabric is then passed through a drying oven, where it is heated to a high temperature to evaporate the solvents and dry the PVC paste.

Printing the design: Once the PVC-coated fabric is dry, it is ready to be printed with the desired design using digital printing or screen printing techniques.

Coating with protective layers: After the printing is complete, a protective layer is applied to the printed surface to enhance the durability and resistance to weathering, UV rays, and other environmental factors.

Cutting and finishing: The finished PVC flex banner is then cut into the desired size and shape using a cutting machine. Grommets and other accessories may be added as required to facilitate installation.

Quality control: Throughout the production process, quality control checks are performed to ensure that the PVC flex banners meet the required specifications for strength, durability, and visual appearance.

Overall, the production of PVC flex banners is a complex process that involves multiple steps and specialized equipment. Each step is critical to ensuring that the final product meets the required quality standards and performs well in a variety of outdoor conditions.

The Classification of PVC Flex Banner

PVC flex banners can be classified based on several criteria, including:

Material: PVC flex banners are typically made from a blend of PVC resin, plasticizers, stabilizers, pigments, and other additives. However, the specific formulation and composition of the PVC paste can vary depending on the desired properties of the final product.

Thickness: PVC flex banners are available in a range of thicknesses, from as thin as 200 microns to as thick as 800 microns or more. Thicker banners tend to be more durable and long-lasting, while thinner banners may be more affordable and suitable for short-term use.

Coating: PVC flex banners can be coated with different types of protective layers to enhance their durability and resistance to environmental factors such as UV rays and weathering. Some banners may have a glossy or matte finish, while others may be textured or embossed for added visual interest.

Printing method: PVC flex banners can be printed using different techniques, such as digital printing or screen printing. Each method has its advantages and disadvantages in terms of cost, quality, and versatility.

Application: PVC flex banners can be used for a variety of applications, such as outdoor advertising, event signage, backdrops, and displays. The specific application may dictate the size, thickness, and other properties of the banner.

Overall, the classification of PVC flex banners can help buyers and users choose the most appropriate product for their specific needs and budget, based on factors such as durability, quality, visual appeal, and ease of installation.