PVC (Polyvinyl Chloride) membrane structure fabric is a type of fabric used in the construction of tensioned membrane structures. These structures are lightweight, durable, and offer a range of design possibilities. PVC membrane fabrics are classified based on various factors, including their composition, surface treatment, and intended applications. Here are the main classifications of PVC membrane structure fabric:

Composition:

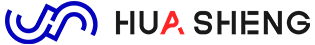

PVC Coated Polyester Fabric: This type of fabric consists of a base polyester fabric that is coated with a layer of PVC. The PVC coating provides waterproofing and enhances the fabric's durability and strength. PVC coated polyester fabrics are commonly used in a wide range of applications, including architectural structures, awnings, tents, and truck covers.

PVC Laminated Polyester Fabric: In this type, the PVC layer is not just a coating but a separate layer that is laminated onto the polyester fabric. Lamination provides additional strength and stability to the fabric, making it suitable for larger-scale structures such as stadiums, exhibition halls, and large canopies.

Surface Treatment:

Glossy PVC Fabric: This type of PVC fabric has a glossy and reflective surface finish. It provides a sleek and modern appearance and is often used in applications where aesthetics and visual appeal are important, such as architectural facades and high-end structures.

Matte PVC Fabric: Matte PVC fabric has a non-reflective and more subdued surface finish. It offers a softer and more natural appearance, making it suitable for applications where a matte or textured look is desired. Matte PVC fabric is commonly used in tensioned ceilings, interior spaces, and temporary event structures.

Fire Retardancy:

Standard PVC Fabric: PVC membrane fabrics are available in standard formulations that offer basic fire resistance properties. These fabrics may comply with local fire safety regulations, but they typically require additional flame-retardant treatments for specific applications.

Fire Retardant PVC Fabric: Fire retardant PVC fabrics are specifically engineered to meet stringent fire safety standards. They are treated with fire-resistant additives during the manufacturing process, providing improved fire resistance and reducing the spread of flames in the event of a fire. Fire retardant PVC fabrics are commonly used in applications where fire safety is a critical requirement, such as public buildings, stadiums, and exhibition spaces.

Translucency:

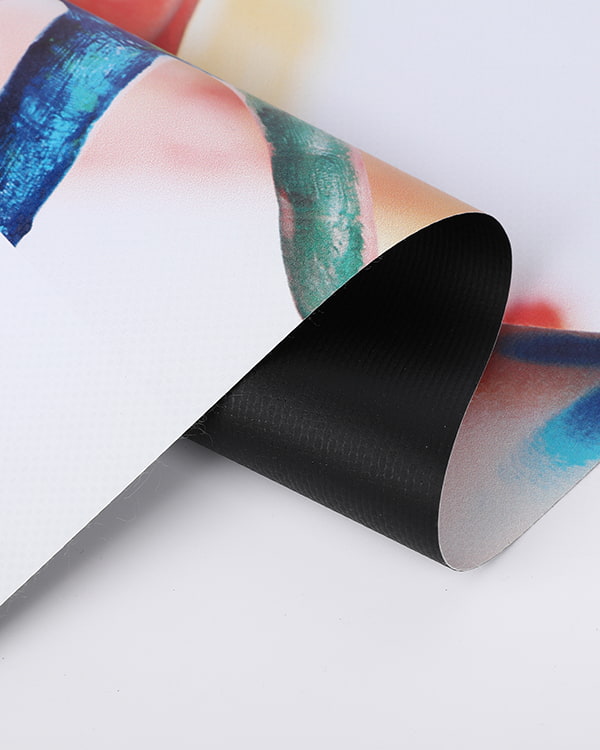

Translucent PVC Fabric: Translucent PVC membrane fabrics allow diffused light transmission, creating a soft and natural illumination effect. They are used in applications where natural daylighting is desired, such as skylights, canopies, and tensile structures that require a balance of light and shade.

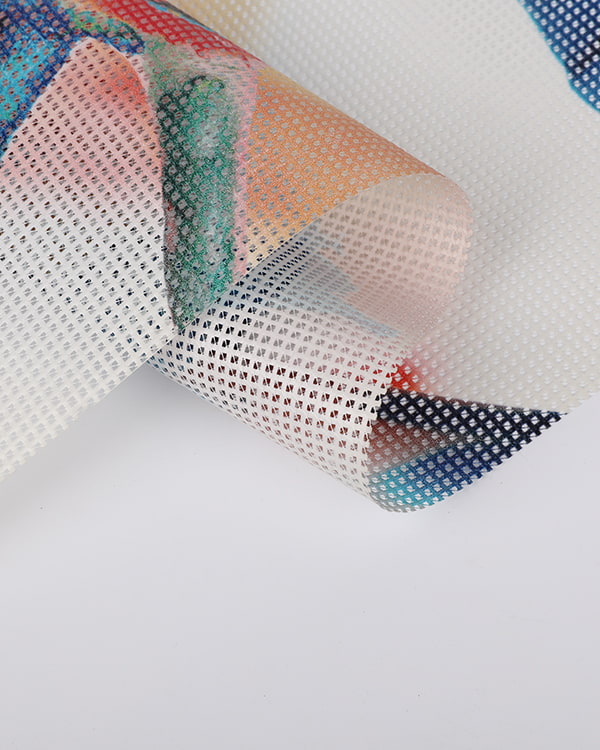

Opaque PVC Fabric: Opaque PVC fabrics do not allow light transmission and provide complete shade and privacy. They are commonly used in applications such as temporary structures, exhibition booths, and projection screens.

English

English 中文简体

中文简体 русский

русский

浙公网安备33048102240301

浙公网安备33048102240301