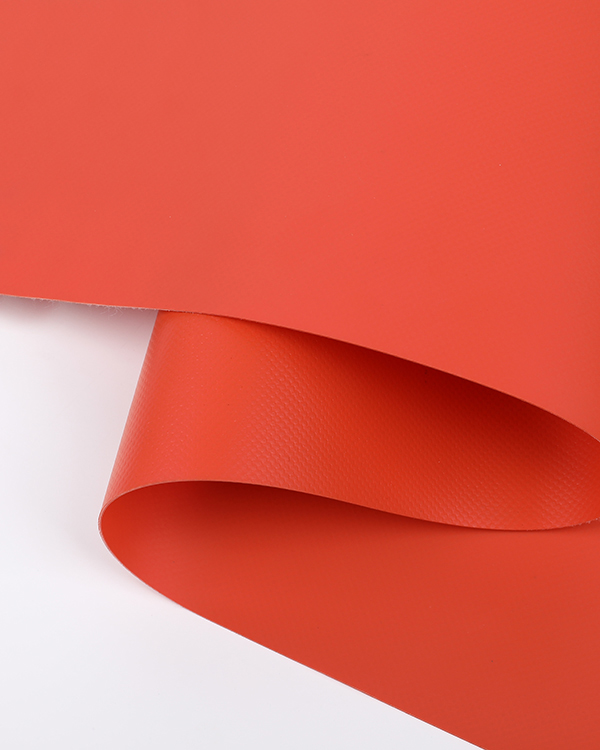

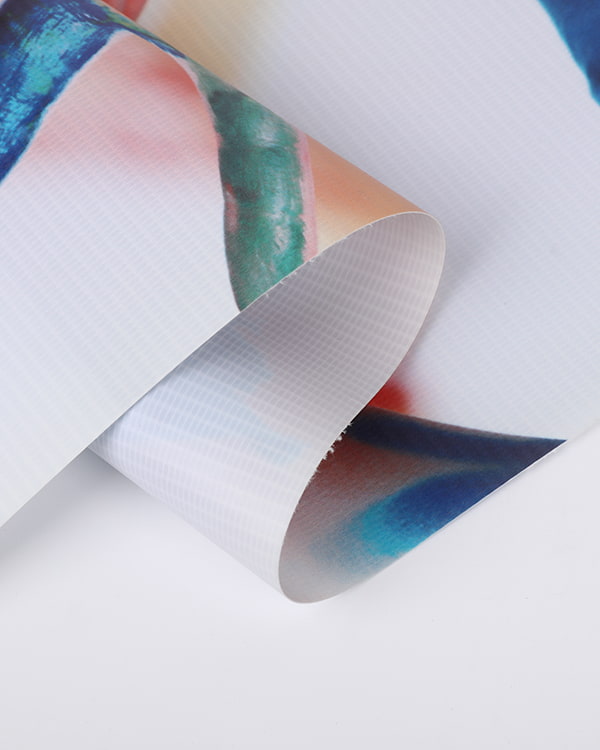

PVC inflatable boat fabric is a fundamental component used in various steps throughout the process of manufacturing an inflatable boat. Its versatile and durable nature makes it an integral part of the boat's construction. Here are the key steps in which PVC inflatable boat fabric is used:

1. Fabric Cutting and Panel Preparation:

- The first step involves cutting the PVC fabric into panels of specific shapes and sizes, according to the boat's design.

- The panels are often cut using precision cutting equipment to ensure accuracy and uniformity.

2. Tube Construction:

- PVC fabric panels are joined together using high-frequency welding or heat sealing techniques to create the boat's inflatable tubes (also known as pontoons or sponsons).

- The seams are carefully constructed to ensure airtightness and structural integrity.

3. Floor and Keel Attachment:

- PVC fabric is used to create the boat's floor and keel components, which provide rigidity and stability to the inflatable boat.

- The fabric panels are attached and sealed to the tubes using welding or sealing methods to create a secure connection.

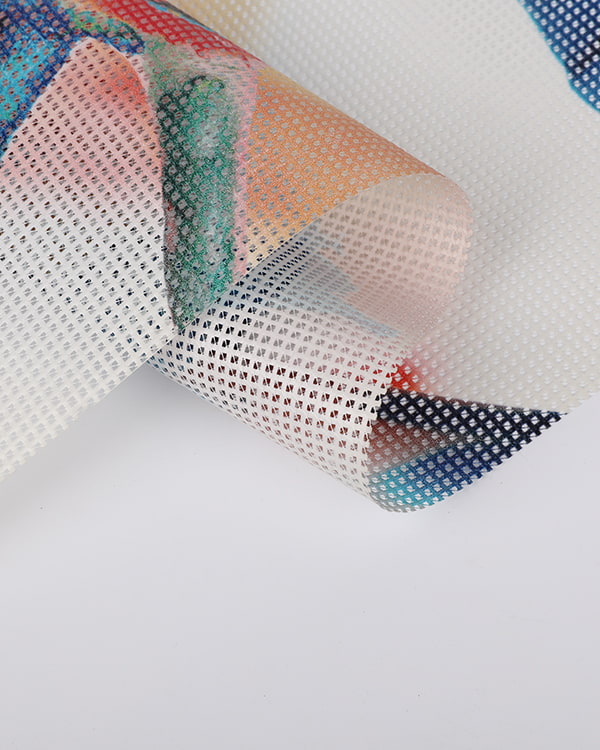

4. Attachment of Reinforcements:

- Additional layers of PVC fabric or reinforcing materials, such as polyester or nylon, are often added to high-stress areas or strategic points on the boat for added strength and durability.

5. Valves and Fittings Installation:

- PVC fabric is used to create sleeves or pockets for the installation of valves, inflation/deflation fittings, and other accessories.

- These components are securely attached to the fabric to ensure proper functionality.

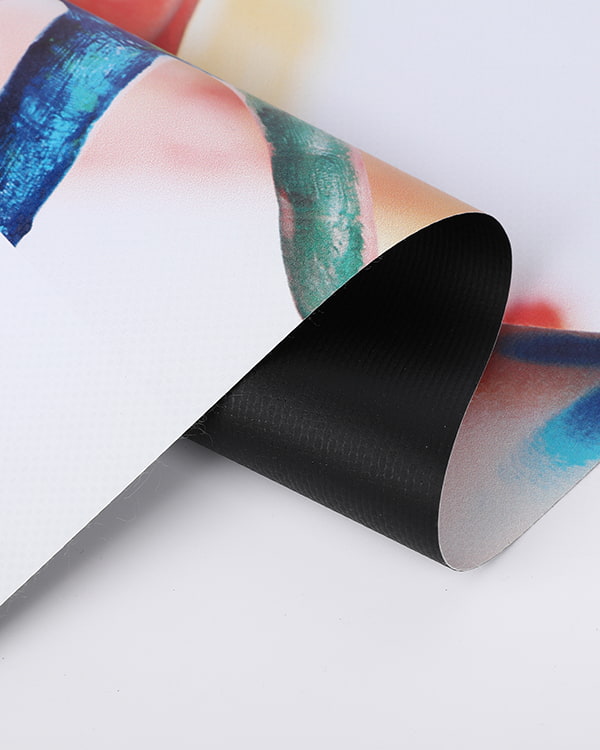

6. Lamination and Coating Application:

- UV-resistant polymer coatings may be applied to the PVC fabric to provide protection against UV radiation and prevent photoaging.

- The PVC fabric may also be laminated with a UV-resistant polymer film to enhance UV protection and durability.

7. Assembly of Boat Components:

- All the fabricated components, including tubes, floor, keel, and attachments, are assembled together to create the complete inflatable boat structure.

- Proper alignment and secure attachment of components are crucial for the boat's overall integrity.

8. Quality Control and Testing:

- Throughout the manufacturing process, quality control measures are carried out to ensure proper seam integrity, airtightness, UV protection, and overall workmanship.

- Leak testing and visual inspections are often performed to identify and address any issues.

9. Finishing and Packaging:

- Once the boat is assembled and passes quality control checks, finishing touches may be applied, such as branding, graphics, and additional accessories.

- The finished inflatable boat is then packaged and prepared for distribution and sale.

PVC inflatable boat fabric is used from the initial stages of cutting and panel preparation to the final steps of assembly, ensuring that the boat is constructed with strength, durability, and UV protection in mind. Proper manufacturing techniques and attention to detail are essential to create inflatable boats that offer reliable performance and longevity.

English

English 中文简体

中文简体 русский

русский

浙公网安备33048102240301

浙公网安备33048102240301