PVC (Polyvinyl chloride) inflatable boat fabric is composed of several key components that provide the necessary properties of strength, flexibility, and durability. The chemical composition of PVC inflatable boat fabric typically includes:

PVC Polymer: PVC is a thermoplastic polymer that serves as the base material for inflatable boat fabric. It is derived from vinyl chloride monomers through polymerization. PVC provides excellent tensile strength, flexibility, and resistance to abrasion, chemicals, and UV radiation.

Plasticizers: Plasticizers are added to the PVC formulation to improve flexibility and make the fabric more pliable. They help to reduce stiffness and enhance the foldability and elongation properties of the fabric. Common plasticizers used in PVC inflatable boat fabric include phthalates or alternative plasticizers that meet specific regulatory requirements.

Stabilizers: Stabilizers are incorporated into the PVC formulation to protect the fabric from degradation caused by heat, UV exposure, and other environmental factors. Stabilizers help to maintain the integrity and longevity of the fabric by preventing color fading, brittleness, and degradation due to oxidation.

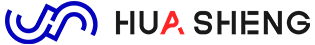

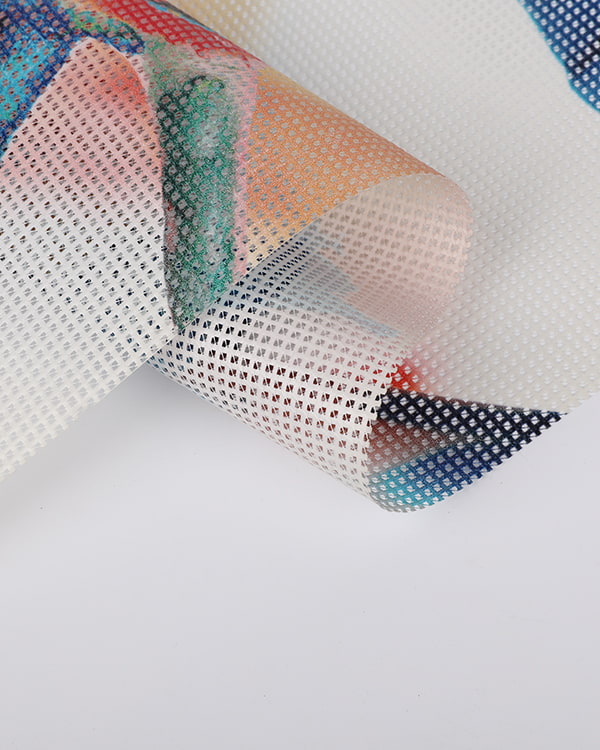

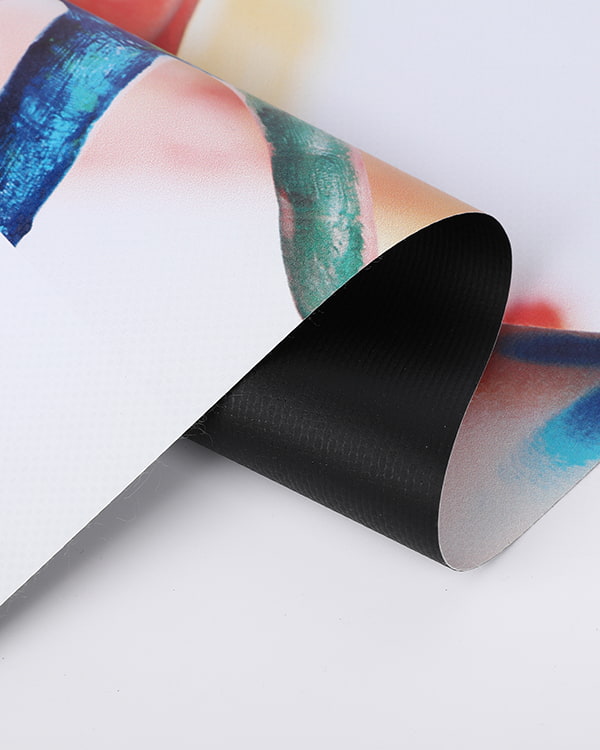

Reinforcements: To enhance the strength and tear resistance of PVC inflatable boat fabric, reinforcement materials are often incorporated. This can include woven fabrics, such as polyester or nylon, which are coated or laminated with PVC to provide additional strength and structural stability.

Pigments and Colorants: Pigments and colorants are added to the PVC formulation to give the inflatable boat fabric its desired color or pattern. These additives help to create visually appealing boat fabrics and allow for customization options.

Additives: Various additives may be included in the PVC formulation to improve specific properties or performance characteristics. This can include antimicrobial agents to inhibit microbial growth, anti-fungal agents to prevent mold and mildew formation, or anti-static agents to reduce static electricity buildup.

It's important to note that the specific chemical composition of PVC inflatable boat fabric can vary between manufacturers and product lines. Different formulations and additive combinations may be used to achieve specific performance requirements or meet regulatory standards.

When purchasing PVC inflatable boat fabric, it's advisable to check the specifications provided by the manufacturer for detailed information on the chemical composition and performance characteristics of the specific fabric you are considering.Meanwhile,PVC (Polyvinyl chloride) inflatable boat fabric serves several important functions that make it suitable for use in inflatable boats. Here are the key functions of PVC inflatable boat fabric:

Air Retention: The primary function of PVC inflatable boat fabric is to retain air within the inflatable chambers, ensuring the boat remains buoyant and stable on the water. The airtight nature of the fabric prevents air leakage, maintaining the boat's structural integrity and keeping it afloat.

Waterproofing: PVC inflatable boat fabric is designed to be highly waterproof. It forms a barrier that prevents water from penetrating the fabric and entering the inflatable chambers. This ensures that the boat remains dry and buoyant even when exposed to water.

Durability and Strength: PVC inflatable boat fabric is known for its durability and strength. It is designed to withstand the rigors of boating activities, including abrasion, impact, and UV exposure. The fabric resists tearing and puncturing, providing a robust and reliable material for inflatable boat construction.

Flexibility and Foldability: PVC inflatable boat fabric offers flexibility and foldability, allowing the boat to be easily inflated, deflated, and packed away for storage or transportation. The fabric can be rolled or folded without causing damage, making it convenient for users to set up and store the boat as needed.

UV Resistance: PVC inflatable boat fabric is typically treated or formulated to have good UV resistance. It can withstand prolonged exposure to sunlight without significant degradation, preventing fading, brittleness, or weakening of the fabric due to UV radiation.

Chemical Resistance: PVC inflatable boat fabric exhibits resistance to various chemicals, including saltwater, gasoline, oils, and common cleaning agents. This chemical resistance helps to protect the fabric from damage or deterioration when in contact with these substances during boating activities.

Ease of Maintenance: PVC inflatable boat fabric is relatively easy to clean and maintain. It can be wiped down with mild soap and water to remove dirt, stains, or debris. The smooth surface of the fabric facilitates easy cleaning and ensures that the boat's appearance is well-maintained.

Customization and Aesthetics: PVC inflatable boat fabric can be manufactured in a wide range of colors, patterns, and textures, allowing for customization and aesthetic choices. This enables boat manufacturers and users to select fabric options that suit their preferences and create visually appealing inflatable boats.

Overall, PVC inflatable boat fabric provides the necessary functions of air retention, waterproofing, durability, flexibility, UV resistance, chemical resistance, ease of maintenance, and aesthetic options, making it a popular choice for inflatable boat construction.

English

English 中文简体

中文简体 русский

русский

浙公网安备33048102240301

浙公网安备33048102240301