Drop stitch fabric can be classified based on various factors such as construction, application, and specific characteristics. Here are a few common classifications of drop stitch fabric:

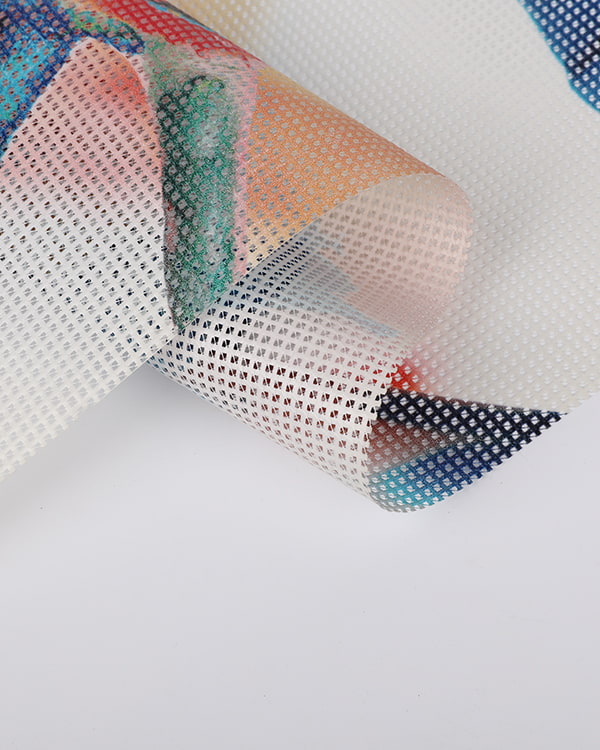

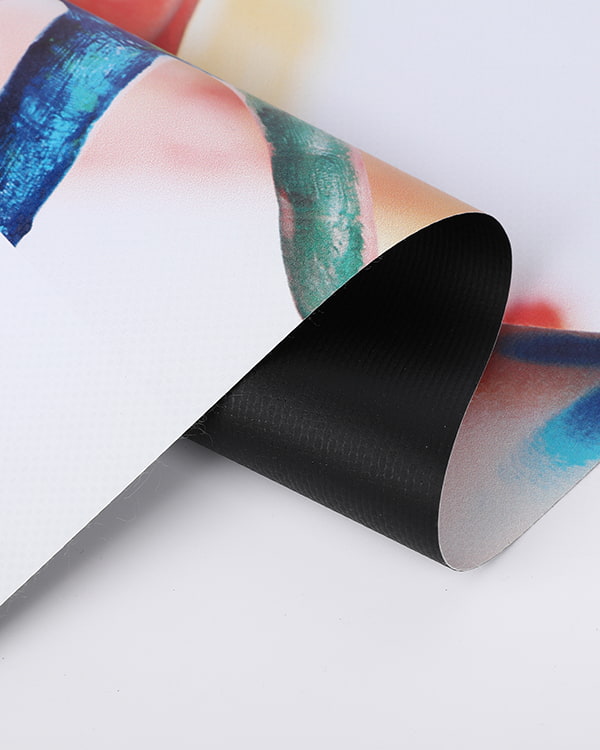

Based on Construction:Single-Layer Drop Stitch Fabric: This type of drop stitch fabric consists of a single layer of threads connecting the top and bottom layers, forming the individual compartments. It provides basic rigidity and is commonly used in lighter inflatable products.Double-Layer Drop Stitch Fabric: Double-layer drop stitch fabric features an additional layer of threads in between the top and bottom layers, resulting in a denser and more rigid structure. It offers increased strength and durability, making it suitable for heavy-duty inflatable applications.

Based on Application:Water Sports Drop Stitch Fabric: Designed specifically for water sports equipment, this type of drop stitch fabric is often used in paddleboards, kayaks, and inflatable boats. It is constructed to withstand water exposure and provide stability and buoyancy.Air Mattress Drop Stitch Fabric: Drop stitch fabric used in air mattresses and inflatable beds is typically designed to provide comfort, support, and air retention properties.Gymnastics and Fitness Drop Stitch Fabric: This type of drop stitch fabric is used in inflatable gymnastics mats, fitness mats, and inflatable gym equipment. It is designed to offer shock absorption, bounce, and stability during exercise routines.Packaging and Protection Drop Stitch Fabric: Drop stitch fabric used in packaging and protection applications, such as corner protectors or inflatable packaging solutions, is engineered to provide cushioning, impact resistance, and product support.

Based on Specific Characteristics:High-Pressure Drop Stitch Fabric: These fabrics are constructed to withstand higher levels of air pressure when inflated, allowing for greater rigidity and stability.Low-Pressure Drop Stitch Fabric: Designed for applications where lower air pressure is required, such as lightweight inflatables or items that require flexibility and ease of folding/storage.

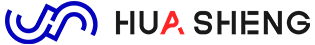

It's important to note that drop stitch fabric may have variations and combinations of these classifications to suit specific product requirements. Manufacturers may develop custom drop stitch fabric formulations to meet the needs of different applications, ensuring optimal performance, strength, and durability.Besides,Drop stitch fabric, also known as inflatable fabric or double-wall fabric, is a unique type of fabric constructed with thousands of threads connecting the top and bottom layers. These threads create small, reinforced compartments that give the fabric its distinctive structure. Drop stitch fabric is primarily used in inflatable products due to its specific functions and characteristics. Here are some key functions of drop stitch fabric:

Inflatability: The main function of drop stitch fabric is its ability to be inflated to create rigid structures. When air is pumped into the fabric, the individual compartments expand and create a firm, stable surface. This inflatability allows for the creation of various inflatable products, such as paddleboards, kayaks, air mattresses, and inflatable boats.

Strength and Durability: The interconnected threads in drop stitch fabric provide exceptional strength and durability. The fabric can withstand high levels of pressure when inflated, making it resistant to punctures and tears. This strength allows inflatable products made with drop stitch fabric to support weight, withstand impacts, and endure rigorous use.

Lightweight and Compact: Drop stitch fabric is lightweight, making it easy to transport and store when deflated. Once deflated, the fabric can be rolled up or folded into a compact size, allowing for convenient storage and portability. This feature is particularly advantageous for outdoor enthusiasts and travelers who require inflatable products that are lightweight and space-efficient.

Stability and Rigidity: When inflated, drop stitch fabric forms a rigid structure that offers excellent stability. The individual compartments created by the threads distribute air pressure evenly, preventing excessive flexing or bending. This stability allows inflatable products like paddleboards and kayaks to remain sturdy and balanced, providing a reliable platform for various activities.

Versatility: Drop stitch fabric is highly versatile and can be used in a wide range of applications. It can be tailored and shaped into different forms and sizes, making it suitable for diverse inflatable products. Additionally, the fabric can be coated or laminated with additional materials to enhance its performance characteristics, such as adding resistance to UV rays, abrasion, or water.

Customizability: Drop stitch fabric can be customized to meet specific design and performance requirements. Manufacturers can adjust the thread density, layer thickness, and overall construction to achieve desired levels of rigidity, strength, and weight. This flexibility allows for the production of inflatable products that cater to different needs and preferences.

Overall, drop stitch fabric's functions of inflatability, strength, durability, lightweight, stability, versatility, and customizability make it a preferred choice for various inflatable products. Its unique construction and properties contribute to the reliability and performance of inflatable items used in water sports, camping, recreation, and other outdoor activities.

English

English 中文简体

中文简体 русский

русский

浙公网安备33048102240301

浙公网安备33048102240301