PVC flex banners are widely used in various applications due to their versatility, durability, and cost-effectiveness. Here are some common applications of PVC flex banners:

Outdoor Advertising: PVC flex banners are extensively used for outdoor advertising purposes, such as billboards, building wraps, hoardings, and signage. Their high durability and weather resistance make them suitable for long-term outdoor use. PVC flex banners can withstand harsh environmental conditions, including sunlight, rain, wind, and temperature fluctuations, ensuring that the advertising message remains visible and intact.

Events and Trade Shows: PVC flex banners are commonly used for event and trade show displays. They can be printed with vibrant graphics, logos, and promotional messages, creating visually appealing backdrops, banners, and exhibition booth displays. PVC flex banners are lightweight and easy to transport, making them convenient for temporary installations and frequent event setups.

Retail and Point-of-Sale Advertising: PVC flex banners find applications in retail environments, including storefronts, shopping malls, and exhibitions. They are used for promoting sales, discounts, new products, and brand awareness. PVC flex banners can be hung or displayed as window graphics, backlit signs, or promotional banners, effectively catching the attention of customers and driving foot traffic.

Stadiums and Sports Events: PVC flex banners are commonly seen in sports stadiums and arenas. They are used for advertising sponsors, displaying team logos, and conveying messages to the audience. PVC flex banners can be large in size, allowing for high visibility even in large stadiums. They are designed to withstand outdoor conditions and can be easily installed on fences, walls, or suspended from the ceiling.

Exhibition Booths and Trade Fairs: PVC flex banners are a popular choice for exhibition booths and trade fairs. They can be used as backdrops, booth dividers, promotional banners, and hanging signs. PVC flex banners are customizable, allowing exhibitors to showcase their brand identity and attract visitors to their booth.

Street Decorations and Festivals: PVC flex banners are utilized for street decorations during festivals, parades, and special events. They can be printed with festive themes, greetings, and artwork, adding color and vibrancy to the surroundings. PVC flex banners are lightweight, making them easy to install and remove, and they can withstand exposure to sunlight and weather conditions.

Construction and Safety Signage: PVC flex banners are also used for construction site signage and safety warnings. They can be printed with cautionary messages, site information, and safety instructions. PVC flex banners are highly visible and durable, ensuring that important messages are communicated effectively in construction zones and hazardous areas.

Meanwhile,The production of PVC flex banners involves several steps. Here is a general overview of the process:

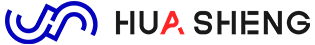

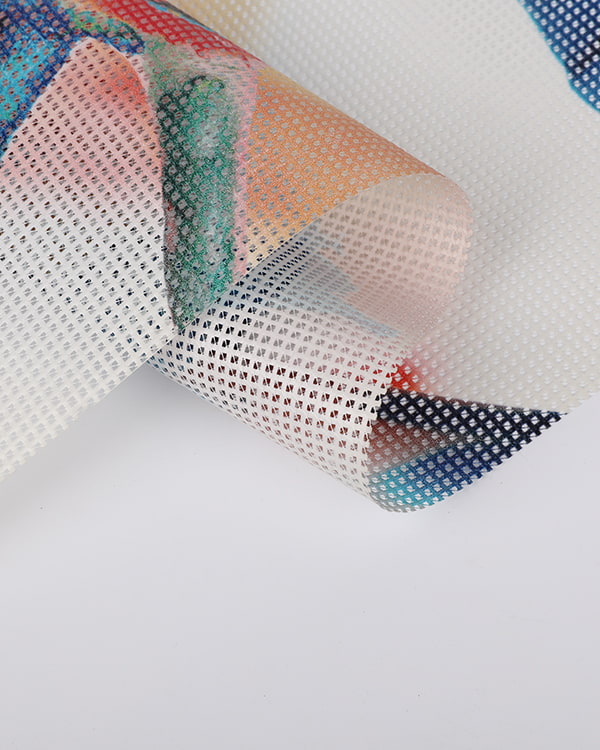

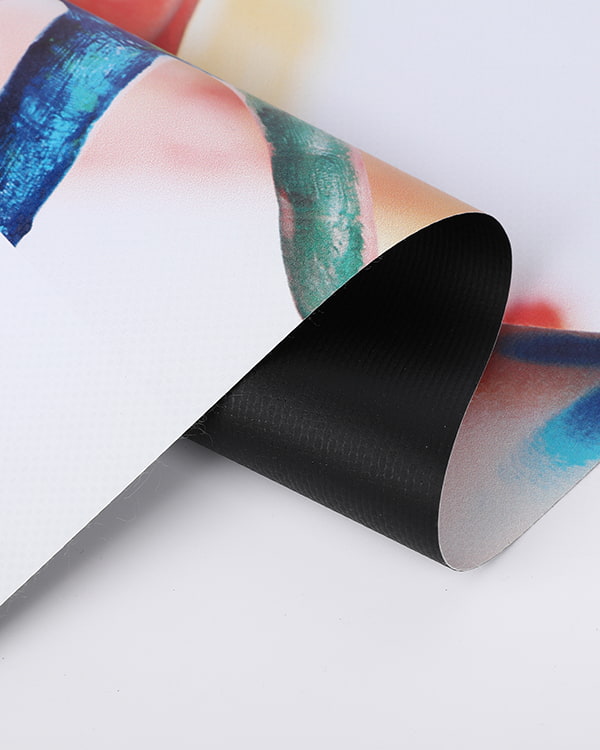

PVC Fabric Preparation: The first step in the production of PVC flex banners is to prepare the PVC fabric. The fabric is made of a base polyester mesh or scrim, which provides strength and stability to the banner. The polyester mesh is coated or laminated with PVC on both sides to create a waterproof and durable material.

Printing: Once the PVC fabric is prepared, the desired graphics, text, and images are printed onto it using large format printing techniques such as digital printing or screen printing. Digital printing is commonly used due to its flexibility and ability to produce high-quality prints with vibrant colors. The printing process involves transferring the desired design onto the PVC fabric using specialized inks or dyes.

Reinforcement and Hemming: After printing, the edges of the PVC flex banner are reinforced and hemmed to enhance its durability and strength. This is typically done by folding and heat-sealing the edges or applying an adhesive tape along the edges. Reinforcement prevents fraying and ensures that the banner remains intact during installation and use.

Eyelet or Grommet Installation: Eyelets or grommets are often added to the corners and along the edges of the PVC flex banner. These metal or plastic rings serve as attachment points for ropes, hooks, or bungee cords, allowing for easy installation and secure fastening of the banner.

Finishing and Trimming: Once the eyelets or grommets are installed, the PVC flex banner is trimmed to the desired size and shape. Excess material or uneven edges are removed to achieve a neat and professional appearance. The banner may also undergo additional finishing processes, such as heat-sealing or stitching, to ensure the edges are properly sealed and reinforced.

Quality Control: Throughout the production process, quality control measures are implemented to ensure that the PVC flex banners meet the required standards. This may involve checking the print quality, color accuracy, dimensions, and overall appearance of the banners. Samples from each batch are typically tested and inspected to verify compliance with quality specifications.

Packaging and Distribution: Once the PVC flex banners pass the quality control checks, they are packaged for distribution. The banners are carefully rolled or folded and placed in protective packaging to prevent damage during transportation. Proper labeling and documentation are provided for easy identification and tracking.

English

English 中文简体

中文简体 русский

русский

浙公网安备33048102240301

浙公网安备33048102240301