Drop stitch fabric, also known as inflatable fabric or double-wall fabric, is a versatile material commonly used in the production of inflatable structures, water sports equipment, and other applications requiring high strength and rigidity.

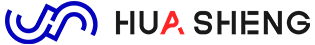

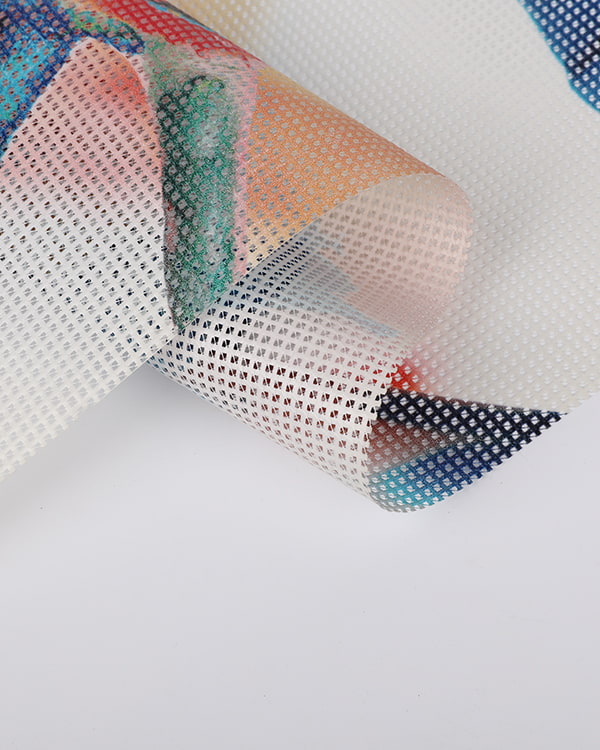

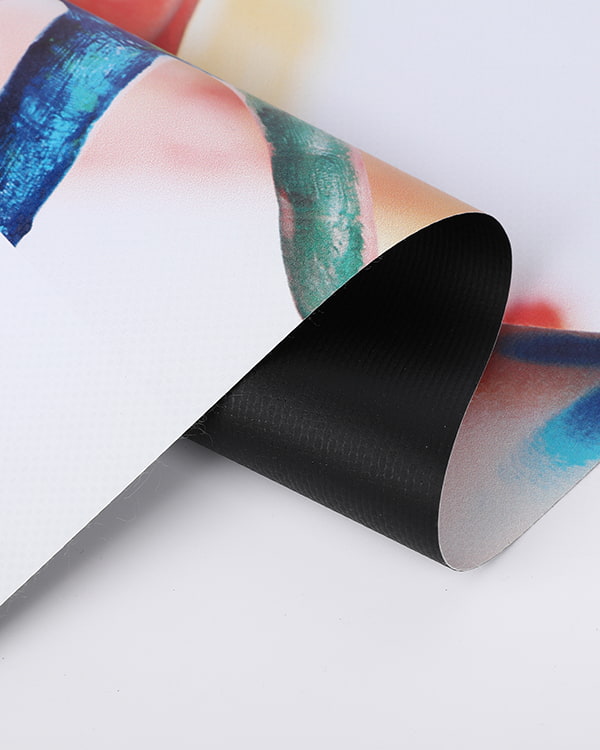

Drop stitch fabric consists of two layers of woven fabric (usually polyester or nylon) connected by thousands of small threads, creating a network of reinforced fibers between the two layers. These threads are evenly spaced and held in place by the tension applied during the manufacturing process. The result is a fabric with a grid-like pattern of interconnected chambers or pockets.

The unique construction of drop stitch fabric allows it to inflate to a high pressure while maintaining its shape and structural integrity. When the fabric is inflated, the interconnected chambers become rigid, providing strength and stability to the structure. The inflated fabric can support weight, withstand pressure, and maintain a flat and stable surface.

Drop stitch fabric is often used in applications such as:

Inflatable Stand-Up Paddleboards (SUPs): Drop stitch fabric is a popular choice for SUPs due to its lightweight, buoyant, and durable properties. The fabric allows the board to maintain its shape and provide stability on water while being inflatable for easy transport and storage.

Inflatable Boats and Kayaks: Drop stitch fabric is utilized in the construction of inflatable boats and kayaks to provide rigidity and strength, making them more stable and seaworthy.

Inflatable Air Mattresses and Gymnastics Mats: The fabric's ability to maintain high pressure and rigidity when inflated makes it suitable for applications such as air mattresses, gymnastics mats, and other inflatable products requiring a stable and supportive surface.

Inflatable Structures: Drop stitch fabric is used in the construction of inflatable structures like tents, event domes, and even temporary housing. The fabric's strength and rigidity allow these structures to withstand wind, rain, and other external forces.

The versatility, lightweight nature, and ability to be easily transported and stored make drop stitch fabric a popular choice in various industries. It provides an efficient and convenient solution for applications where portability, strength, and rigidity are essential.Meanwhile,Drop stitch fabric offers several key functions and benefits in various applications. Here are some of its primary functions:

Structural Strength: Drop stitch fabric provides excellent structural strength and rigidity when inflated. The interconnected chambers or pockets create a network of reinforced fibers that distribute pressure evenly, allowing the fabric to withstand significant weight and maintain its shape.

Stability and Support: Inflatable products made with drop stitch fabric, such as paddleboards, boats, and air mattresses, offer stability and support. The fabric's ability to maintain high pressure creates a firm and stable surface that can withstand dynamic forces and weight distribution.

Lightweight and Portable: Drop stitch fabric is lightweight compared to traditional solid materials used for similar purposes. This makes inflatable products constructed with drop stitch fabric highly portable, easy to transport, and convenient for storage when deflated.

Versatility: Drop stitch fabric is highly versatile and can be shaped and tailored to different applications. It can be cut, sewn, and heat-sealed to create customized inflatable structures of various shapes and sizes.

Impact Resistance: The layered construction of drop stitch fabric provides excellent impact resistance. It can withstand collisions, bumps, and rough handling without easily puncturing or tearing, making it durable and suitable for outdoor and active use.

Waterproof and Airtight: When properly sealed and inflated, drop stitch fabric creates a waterproof and airtight barrier. This property ensures that inflatable products made with drop stitch fabric remain watertight and airtight during use, enhancing their functionality and performance.

Easy Maintenance: Drop stitch fabric is relatively easy to clean and maintain. It can be wiped down or washed with mild soap and water, and any punctures or damages can often be repaired using patching techniques specific to the fabric.

Customizability: Drop stitch fabric can be manufactured with different coatings, finishes, and colors to meet specific requirements. This allows for customization in terms of appearance, performance, and functionality.

These functions make drop stitch fabric a desirable material for various applications, ranging from water sports equipment to inflatable structures. Its combination of strength, stability, portability, and versatility makes it a practical choice in industries such as outdoor recreation, water sports, event management, and emergency response.

English

English 中文简体

中文简体 русский

русский

浙公网安备33048102240301

浙公网安备33048102240301